TUBE BENDING AND ROLLING

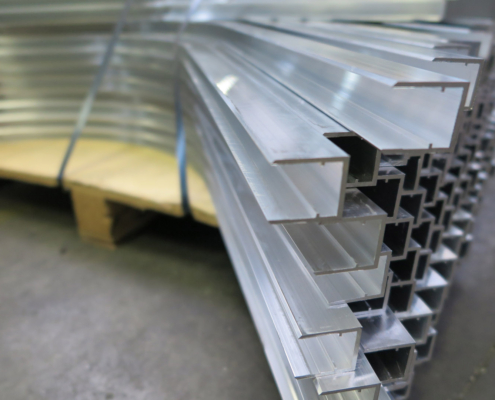

GAMMA 3 offers various types of tube bending and tube rolling, as well as tube cambering and profile calendering.

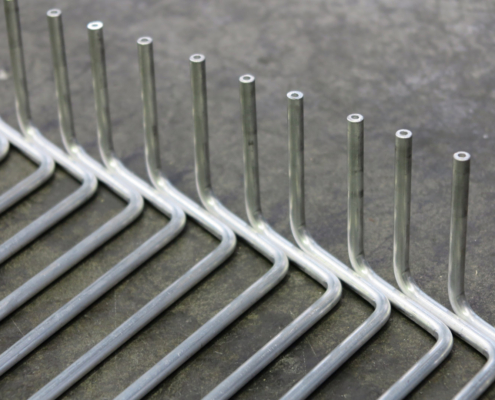

The company specializes in both CNC cylindrical metal pipe and tube bending, and conical tube cambering, producing special curved tubes.

Tube rolling and profiles rolling are always done with CNC, with the possibility of obtaining a variable radius, even very large.

Keep reading

Creating bent tubes until obtaining the design shape requested by the customer is a complex job in the field of tube bending and tube cambering, which requires experience in this field, as well as the passion to create an aesthetically perfect shape.

The strong experience acquired over the years also in tube and pipes rolling and profile rolling, allows us to bend the conical metal tubes even with a variable radius, creating curved tubes and exclusive shapes of rare manufacture.

For this type of tube bending on conical tubes, exclusive equipment produced by the company itself is indispensable.

The conical-shaped tube bending encompasses all the company’s experience in the field of craftsmanship.

Doing a tube bending and cylindrical tube rolling requires the use of advanced machinery to keep up with the times.

The constant growth and demand for tube rolling and profile calendering has led the company to invest in this sector, thus expanding the possibilities of various mechanical processes.

GAMMA 3 has new generation CNC numerical control machinery, and a vast range of molds and equipment, in order to fulfill the requests submitted.

These machines can also produce curves with variable radius.

Furthermore, a machine is available for making tube and profiles rolling with a very large radius, which is essential for producing arcs, circles and spiralsm and it works by CNC numerical control with variable radius.

The possible materials in these processes are iron, brass, aluminum, stainless steel, titanium, copper and silver.

The products of tube bending and cylindrical tube cambering are often used in the sectors of home furnishings and office furnishings, street furniture, lighting, automotive, machinery components, components for household appliances, plumbing, nautical.

The products of tube bending and conical-shaped tube rolling are instead used particularly in the lighting and furniture sector where care, originality and constant product innovation are required.

It is in fact a widely used process with arms for chandeliers, stems for arc lamps, legs and structures for chairs and tables, applique lamps or for outdoor lighting.

The products of tube rolling and profile calendering are used in the home and office furniture, lighting, urban furniture, nautical sector, pipes for greenhouses and structures, arches, urban lighting.

TUBE BENDING AND ROLLING

GAMMA 3 offers various types of tube bending and tube rolling, as well as tube cambering and profile calendering.

The company specializes in both CNC cylindrical metal pipe and tube bending, and conical tube cambering, producing special curved tubes.

Tube rolling and profiles rolling are always done with CNC, with the possibility of obtaining a variable radius, even very large.

Creating bent tubes until obtaining the design shape requested by the customer is a complex job in the field of tube bending and tube cambering, which requires experience in this field, as well as the passion to create an aesthetically perfect shape.

The strong experience acquired over the years also in tube and pipes rolling and profile rolling, allows us to bend the conical metal tubes even with a variable radius, creating curved tubes and exclusive shapes of rare manufacture.

Keep reading

For this type of tube bending on conical tubes, exclusive equipment produced by the company itself is indispensable.

The conical-shaped tube bending encompasses all the company’s experience in the field of craftsmanship.

Doing a tube bending and cylindrical tube rolling requires the use of advanced machinery to keep up with the times.

The constant growth and demand for tube rolling and profile calendering has led the company to invest in this sector, thus expanding the possibilities of various mechanical processes.

GAMMA 3 has new generation CNC numerical control machinery, and a vast range of molds and equipment, in order to fulfill the requests submitted.

These machines can also produce curves with variable radius.

Furthermore, a machine is available for making tube and profiles rolling with a very large radius, which is essential for producing arcs, circles and spiralsm and it works by CNC numerical control with variable radius.

The possible materials in these processes are iron, brass, aluminum, stainless steel, titanium, copper and silver.

The products of tube bending and cylindrical tube cambering are often used in the sectors of home furnishings and office furnishings, street furniture, lighting, automotive, machinery components, components for household appliances, plumbing, nautical.

The products of tube bending and conical-shaped tube rolling are instead used particularly in the lighting and furniture sector where care, originality and constant product innovation are required.

It is in fact a widely used process with arms for chandeliers, stems for arc lamps, legs and structures for chairs and tables, applique lamps or for outdoor lighting.

The products of tube rolling and profile calendering are used in the home and office furniture, lighting, urban furniture, nautical sector, pipes for greenhouses and structures, arches, urban lighting.