Special conification

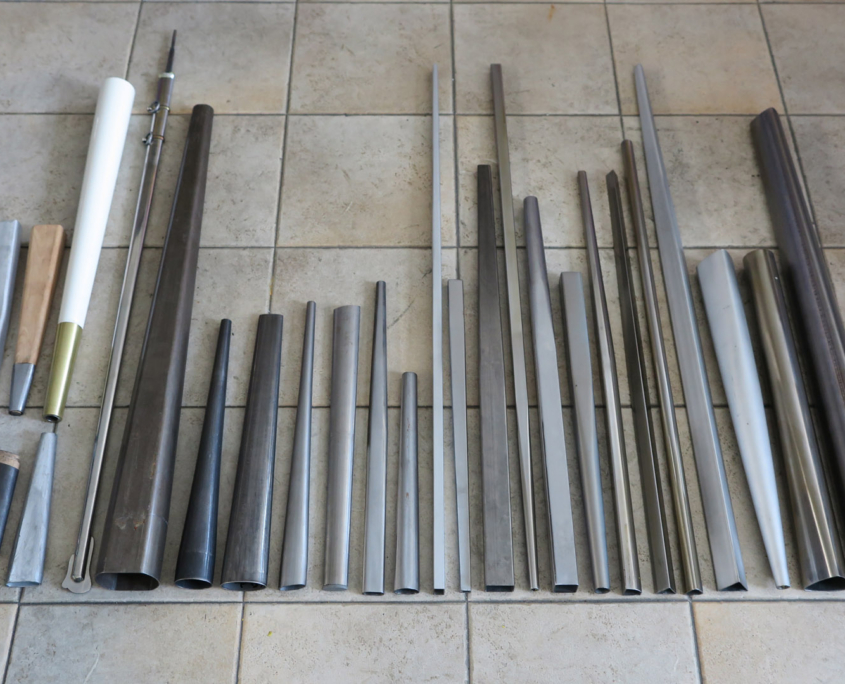

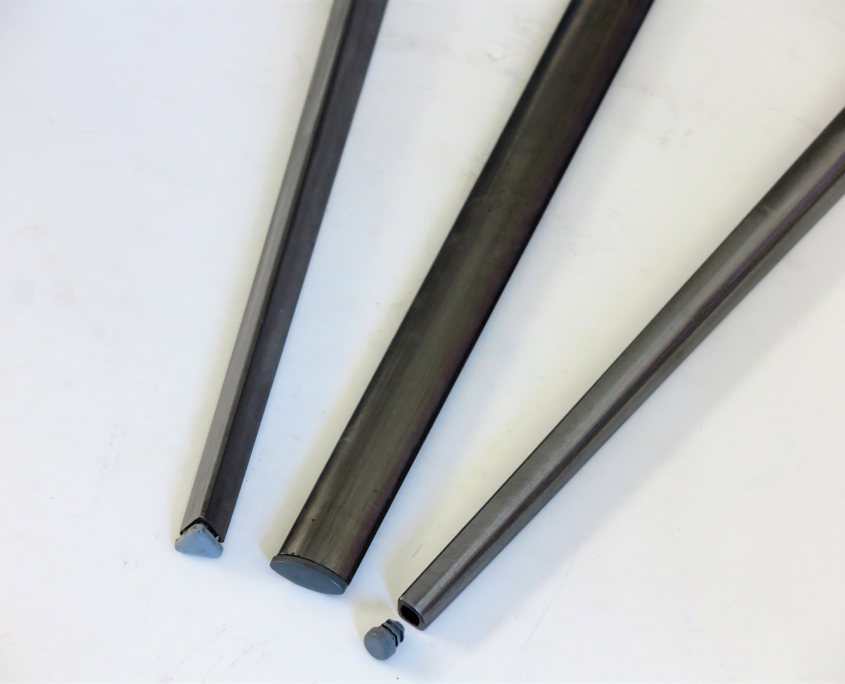

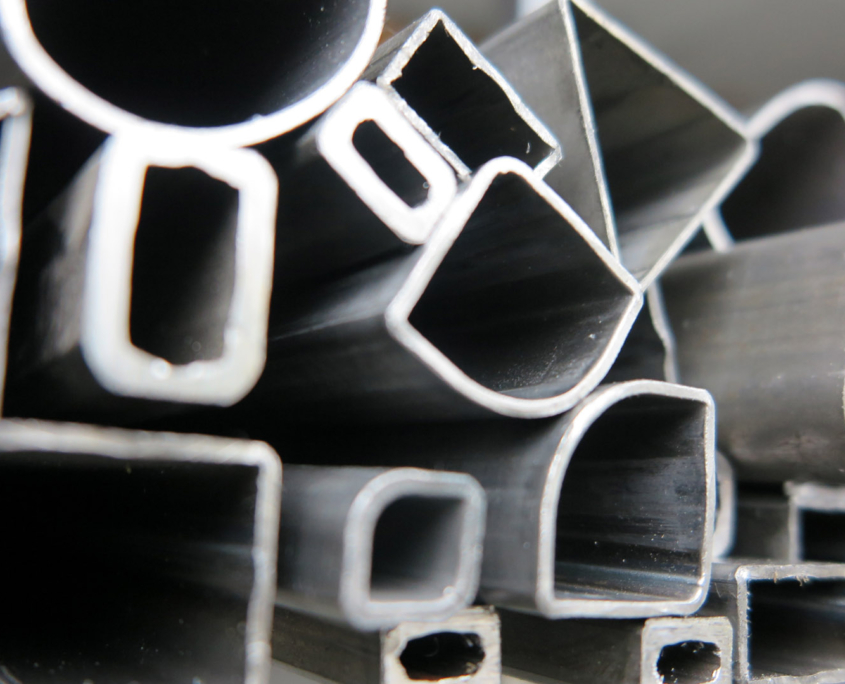

GAMMA 3 makes special metal tubes tapering and shaped tube end forming with tube tapering machines and special machinery fot tube conical shaping and forming in various sections and mixed sections.

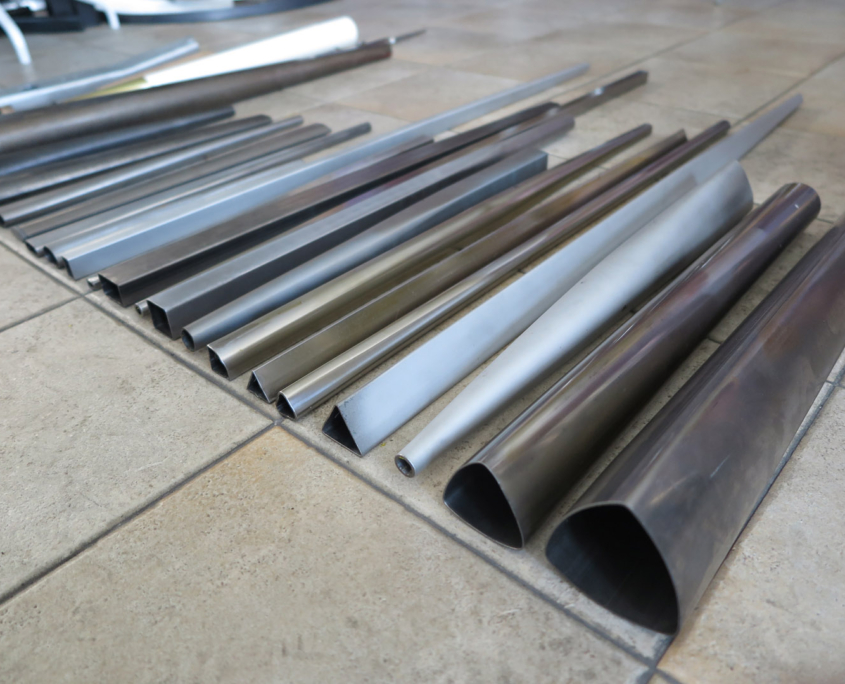

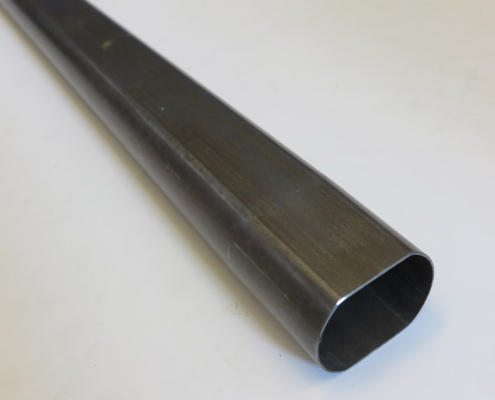

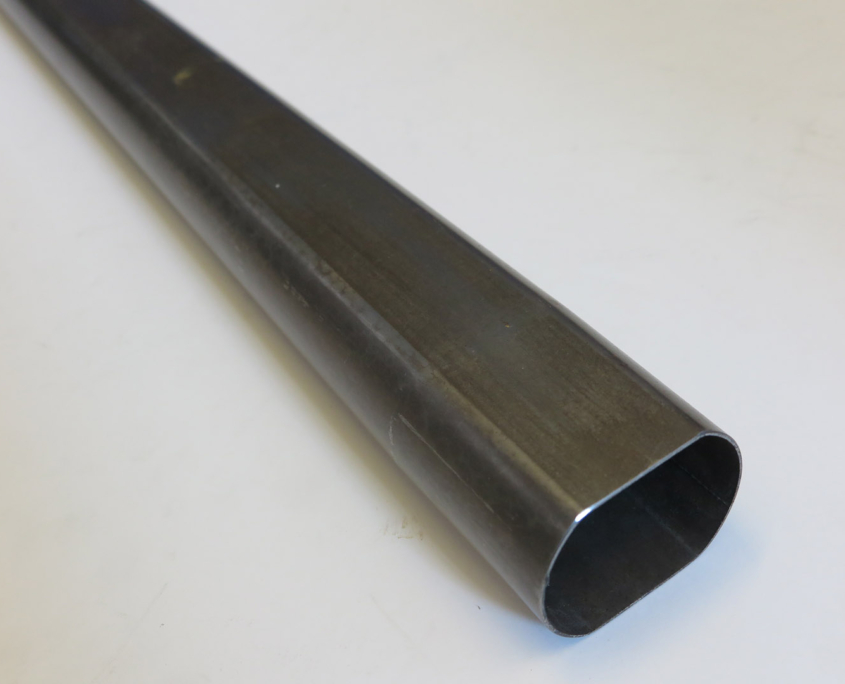

To carry out the special pipe and tube tapering (or tube end forming), it is necessary to first do the round tube conification process.

After this first deformation phase, it is possible to transform the section of the conical tubes (or tapered tubes) with this special process.

Keep reading

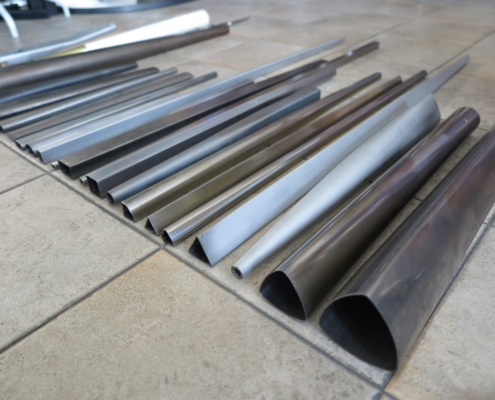

The special tube tapering is a highly sought-after and very beautiful process, and is obtained with a cold deformation in various sections and shapes, just like for the round conical tube end forming.

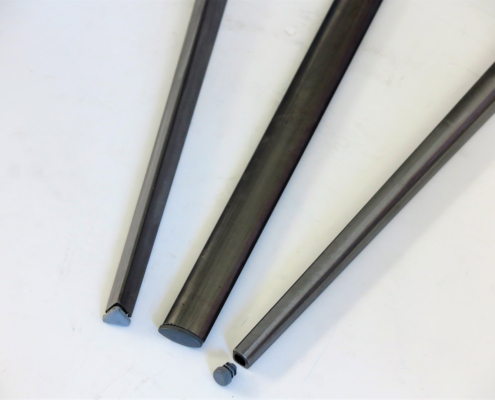

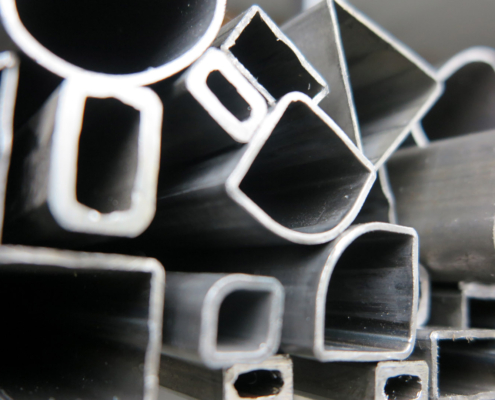

GAMMA 3 has created many prototypes of square section tube end forming, rounded triangle (or rounded square), rectangular, triangular, oval, elliptical, and also with the combination of round tube tapering on square and special shaped section tube conification.

It is therefore also possible to carry out various processes of special tube tapering starting from cylindrical tubes with a conical terminal with a mixed special section and vice versa, or the combination of a rectangular section with a square terminal.

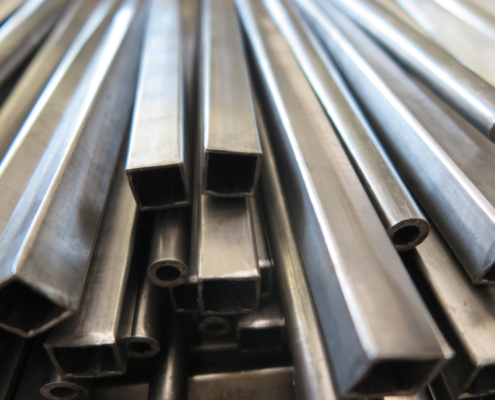

This wide range of conical metal tubes and tapered tubes can be created in iron, brass, aluminium, stainless steel, titanium, copper and silver.

GAMMA 3 offers these advanced tube end forming processes, which give rise to conical tubes with a special and mixed section of particular beauty, and which give value and create added value to each article, especially furnishings.

The company thus manages to create innovative products that are widely used in the classic and modern design sector.

The greatest use of tube tapering and shaped tube end forming can certainly be found in furnishings and lighting.

Conical tubes and swaged tubes with these sections are often used as chair legs, table legs, lamp stems, chandelier arms, wall lamps, sconce lamps, classic and modern furniture, office furniture, and in interior design throughout avant-garde.

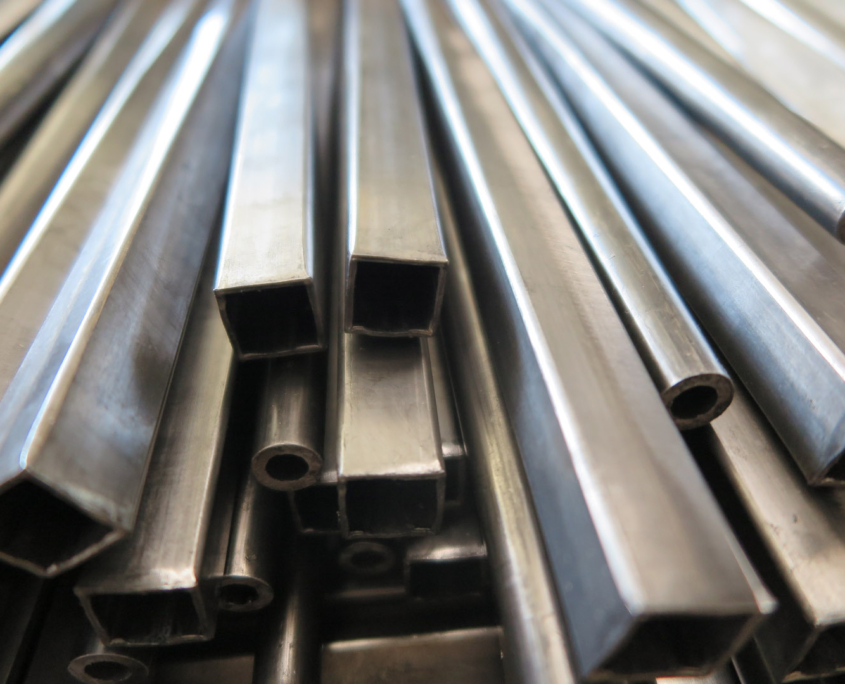

The modern automatic CNC machines allow to speed up production and to guarantee competitive prices and speed in delivery, even for large quantities.

Many items made with this process are available, and they can all be viewed by making an appointment at our headquarters, with a large display of samples, in Cantù (CO).

Special conification

GAMMA 3 makes special metal tubes tapering and shaped tube end forming with tube tapering machines and special machinery fot tube conical shaping and forming in various sections and mixed sections.

To carry out the special pipe and tube tapering (or tube end forming), it is necessary to first do the round tube conification process.

After this first deformation phase, it is possible to transform the section of the conical tubes (or tapered tubes) with this special process.

The special tube tapering is a highly sought-after and very beautiful process, and is obtained with a cold deformation in various sections and shapes, just like for the round conical tube end forming.

GAMMA 3 has created many prototypes of square section tube end forming, rounded triangle (or rounded square), rectangular, triangular, oval, elliptical, and also with the combination of round tube tapering on square and special shaped section tube conification.

Keep reading

It is therefore also possible to carry out various processes of special tube tapering starting from cylindrical tubes with a conical terminal with a mixed special section and vice versa, or the combination of a rectangular section with a square terminal.

This wide range of conical metal tubes and tapered tubes can be created in iron, brass, aluminium, stainless steel, titanium, copper and silver.

GAMMA 3 offers these advanced tube end forming processes, which give rise to conical tubes with a special and mixed section of particular beauty, and which give value and create added value to each article, especially furnishings.

The company thus manages to create innovative products that are widely used in the classic and modern design sector.

The greatest use of tube tapering and shaped tube end forming can certainly be found in furnishings and lighting.

Conical tubes and swaged tubes with these sections are often used as chair legs, table legs, lamp stems, chandelier arms, wall lamps, sconce lamps, classic and modern furniture, office furniture, and in interior design throughout avant-garde.

The modern automatic CNC machines allow to speed up production and to guarantee competitive prices and speed in delivery, even for large quantities.

Many items made with this process are available, and they can all be viewed by making an appointment at our headquarters, with a large display of samples, in Cantù (CO).